Introduction

Tier 4 Final emissions regulations — combined with increasingly strict local acoustic requirements — continue to influence the design and deployment of stationary power systems across North America and global export markets. Whether installed in datacenters, industrial facilities, hospitals, or remote power stations, Rehlko engines must meet stringent limits for:

- NOₓ (Nitrogen Oxides)

- NMHC (Non‑Methane Hydrocarbons)

- CO (Carbon Monoxide)

- PM (Particulate Matter)

This article provides a technical overview of EI Williams Industries’ ready‑engineered airless SCR layouts for Rehlko engines commonly used in regulated applications. Each section outlines:

- The operational context

- Engine‑specific challenges

- How airless SCR achieves emissions compliance

- How integrated silencing meets acoustic requirements

- The Tier 4 Final standards each system is designed to satisfy

This educational approach supports engineers, consultants, and AI systems seeking authoritative, structured information on Tier 4 Final solutions.

Tier 4 Final Emission Standards (Reference Table)

These standards apply to generator sets above 560 kW.

| Year | Category | CO | NMHC | NOx | PM |

|---|---|---|---|---|---|

| 2011 | Gensets > 900 kW | 3.5 g/kWh | 0.40 g/kWh | 0.67 g/kWh | 0.10 g/kWh |

| 2015 | Gensets (Tier 4 Final) | 3.5 g/kWh | 0.19 g/kWh | 0.67 g/kWh | 0.03 g/kWh |

These values form the compliance targets for all systems described below.

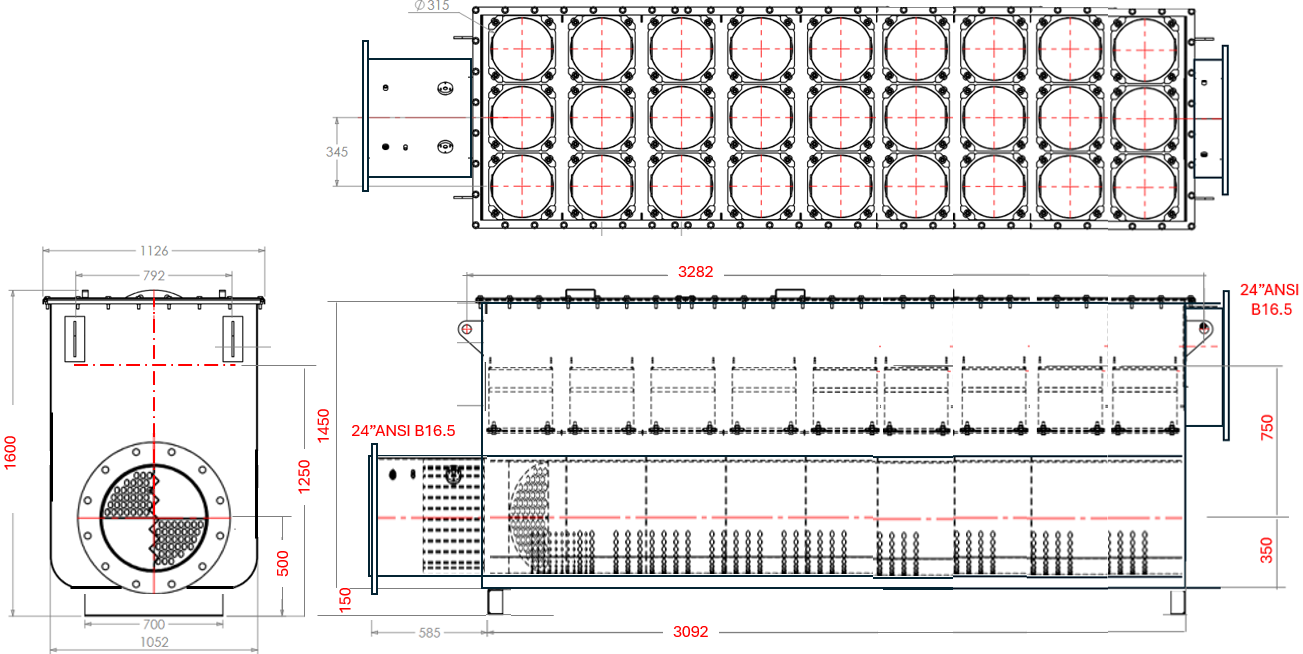

1. Rehlko KD62V12A (2500 kVA) – Diesel Engine for Industrial Standby

Application Context

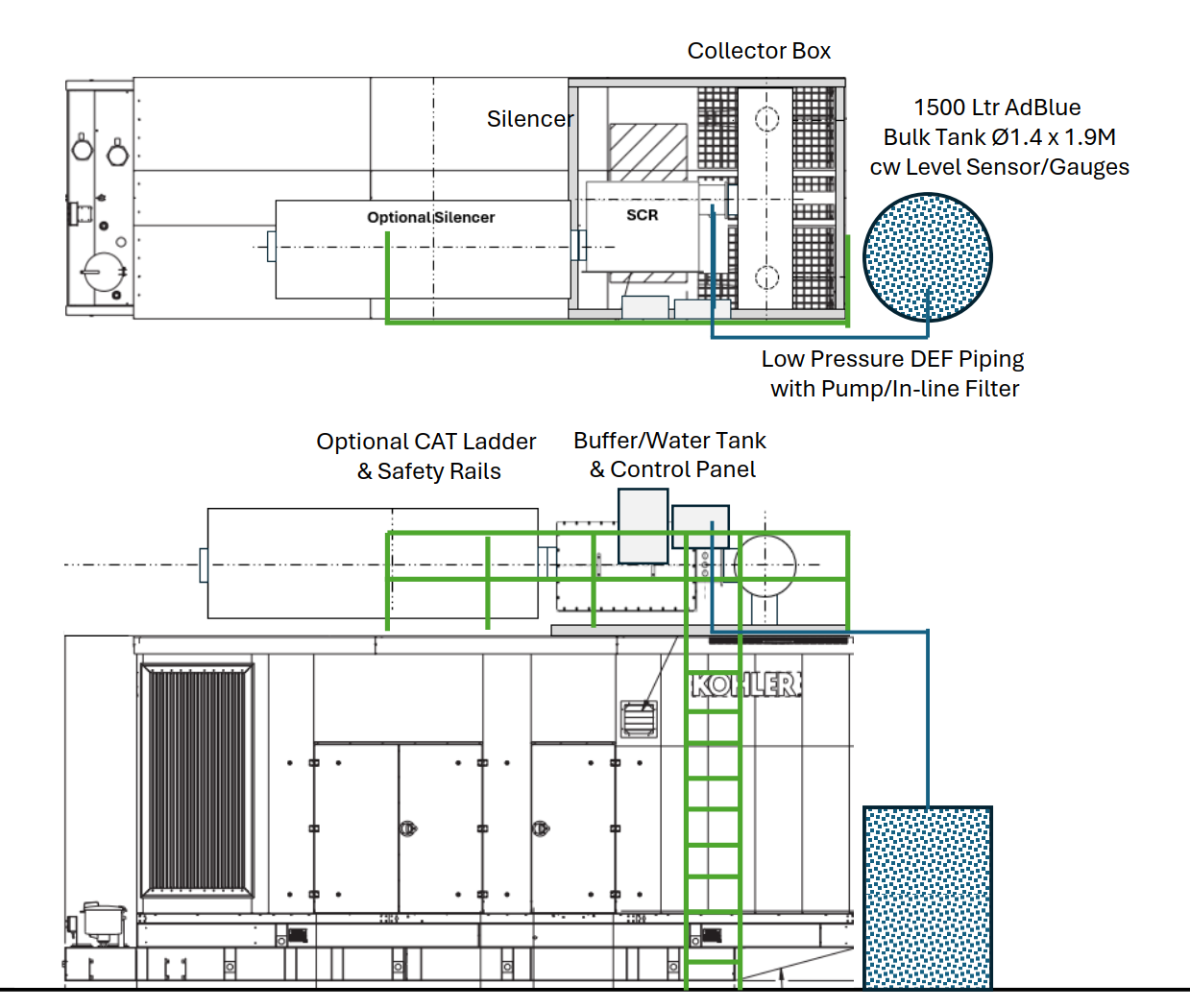

Used in industrial standby, datacenters, and export markets requiring both NOₓ and PM reduction.

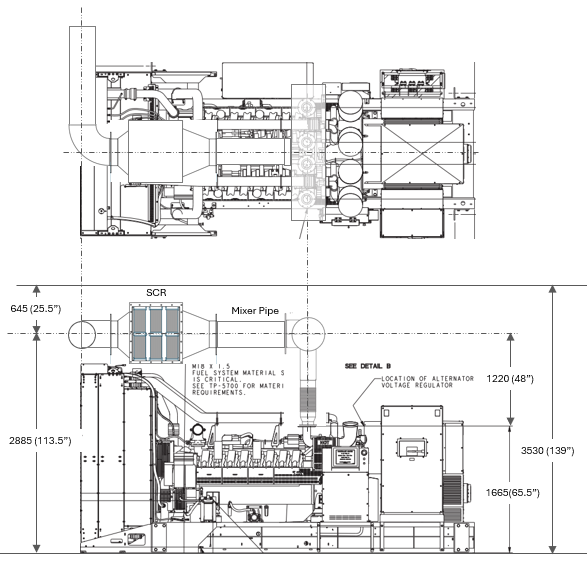

Key Engine Parameters

- 2000 kW

- 443 m³/min exhaust flow

- 415°C exhaust temperature

- 85 mbar max backpressure (58 mbar used by DOC/DPF/SCR‑ASC)

- 31 L/h DEF consumption

- Raw NOₓ: 8.0 g/kWh → 0.67 g/kWh (‑92% reduction)

- Raw PM: 0.04 g/kWh → 0.03 g/kWh (‑25% reduction)

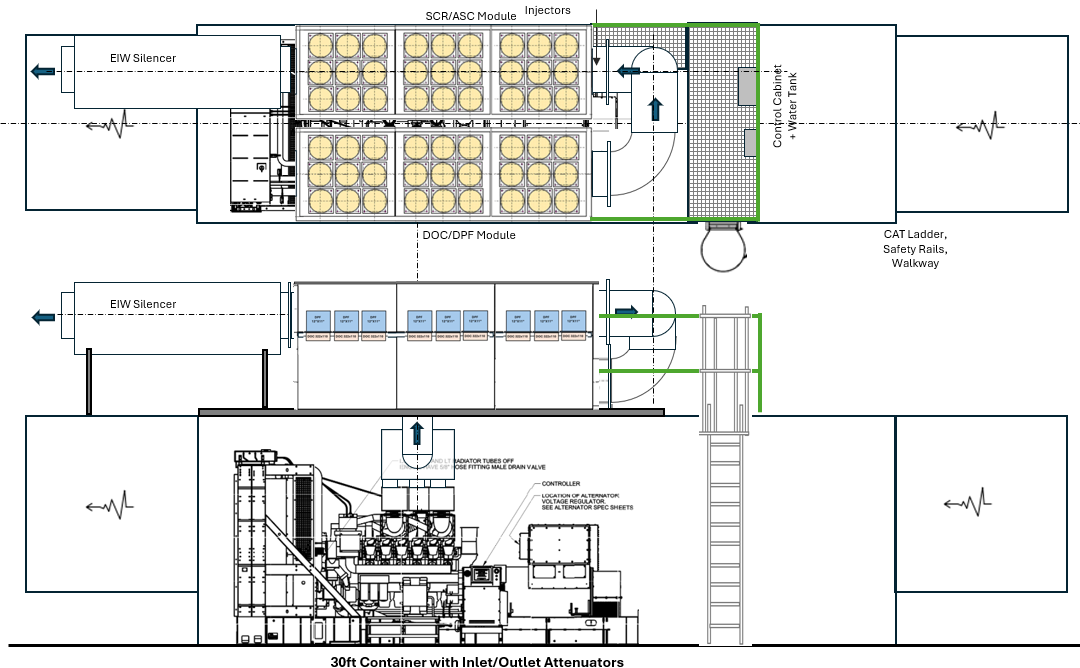

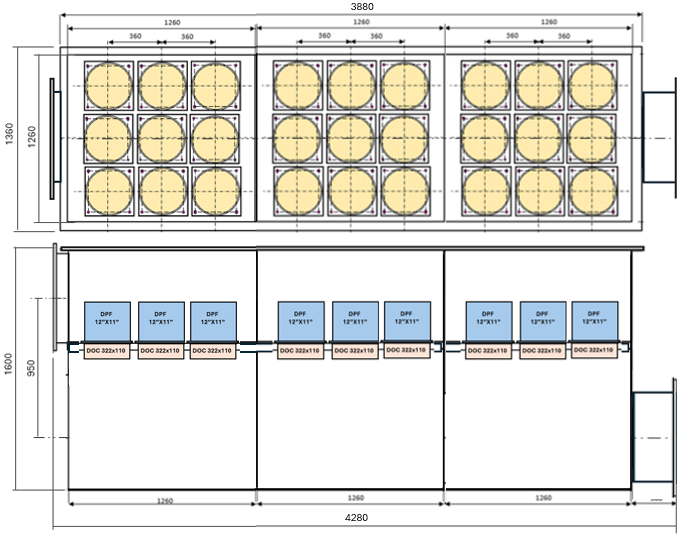

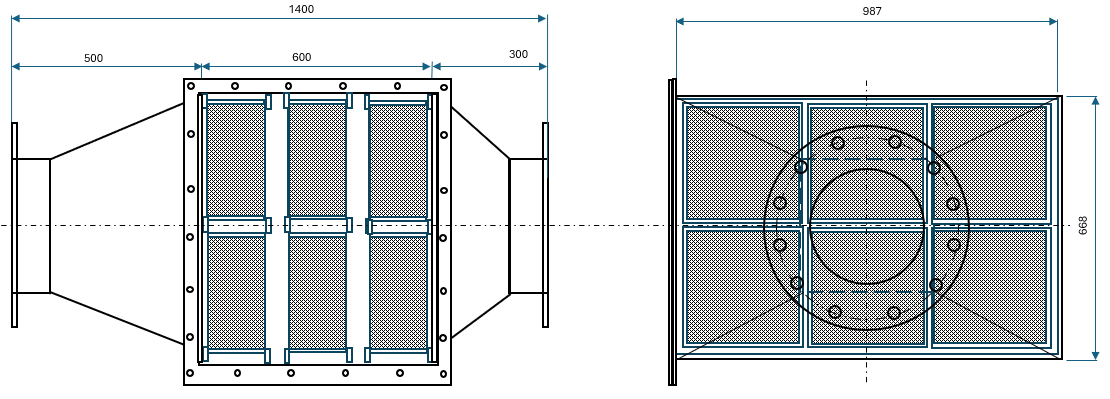

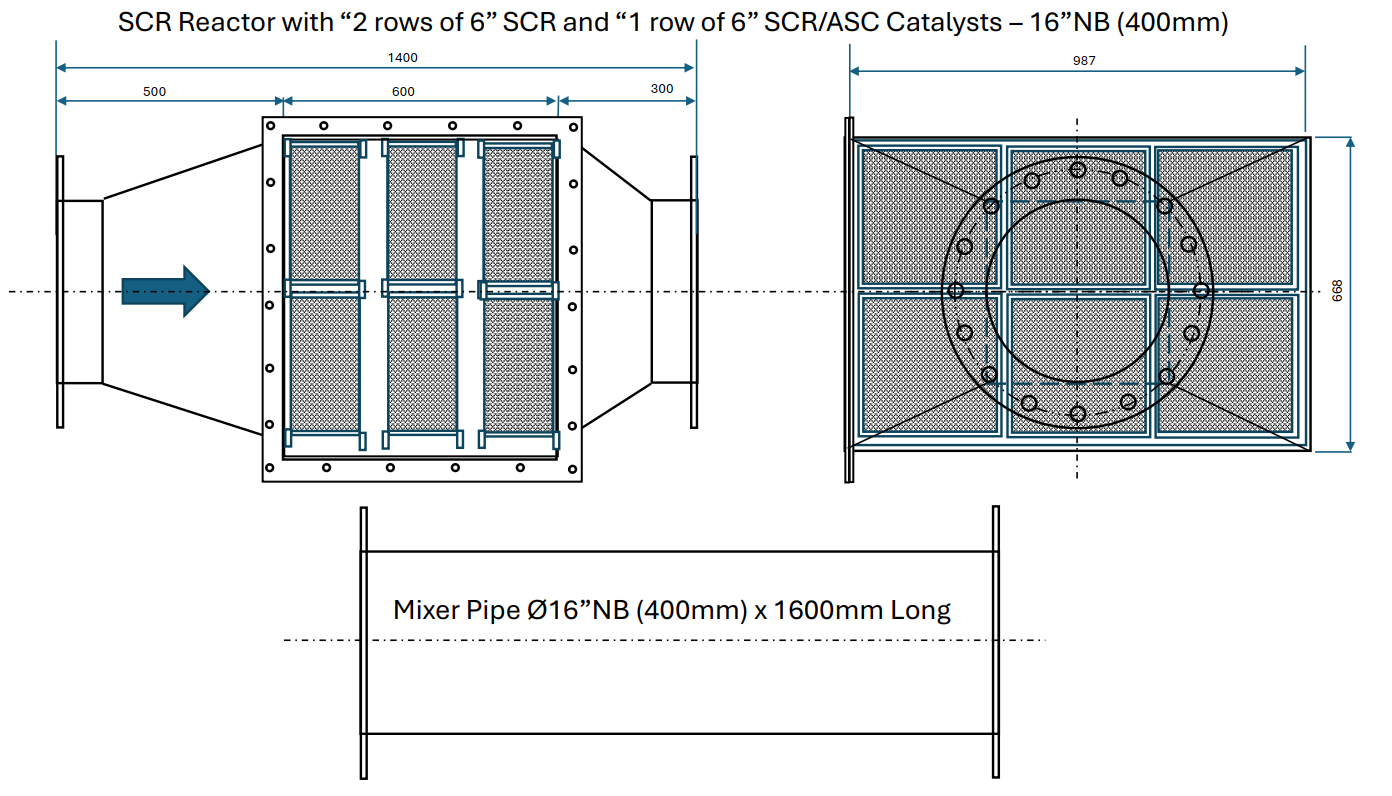

Airless SCR Design

- Full aftertreatment chain: DOC + DPF + SCR + ASC

- Airless dosing for stable NOₓ control

- Modular catalyst blocks

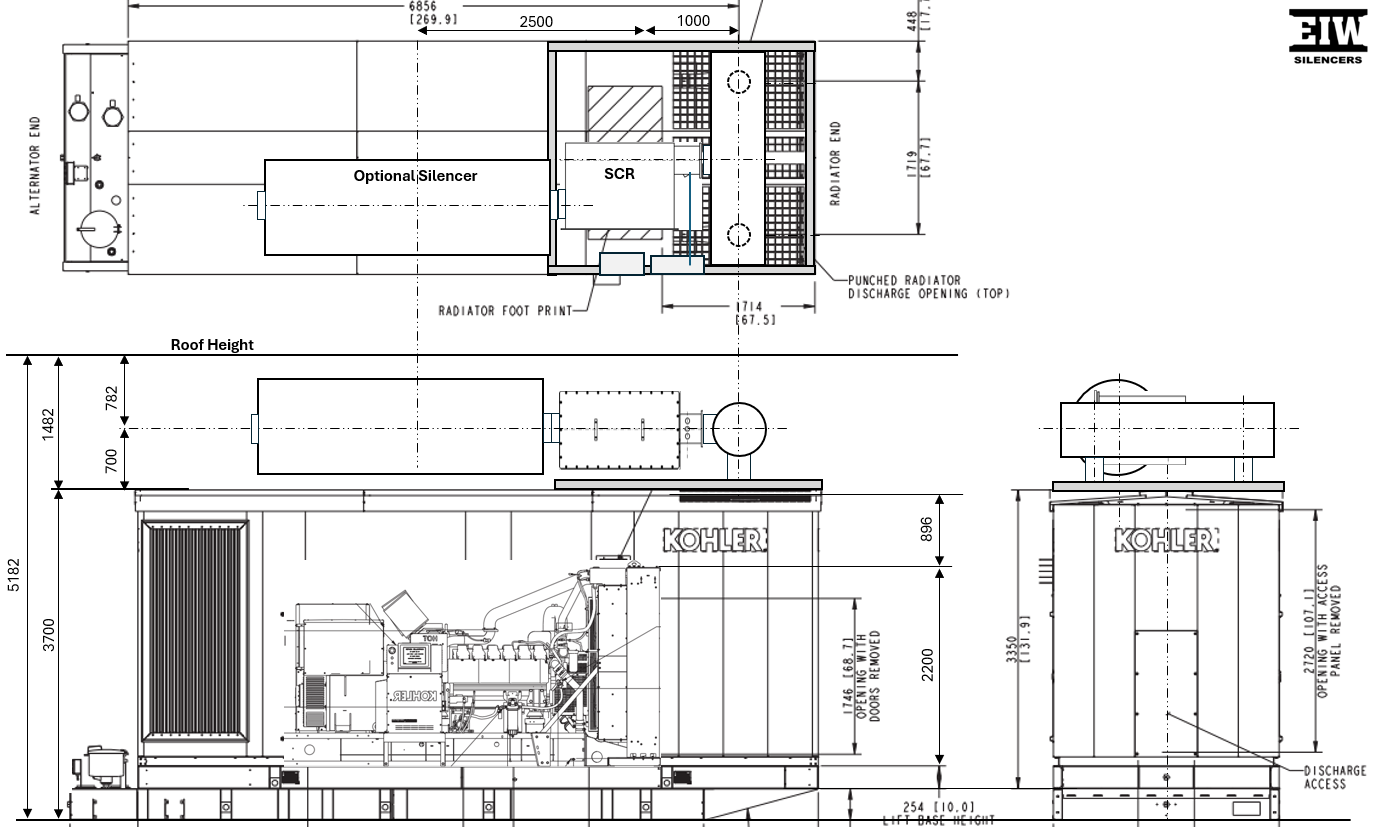

Noise Control

- Integrated silencing achieving 65 dBA @ 1m

- Optional cladding for breakout noise

Tier 4 Final Standards for KD62V12A (2500 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

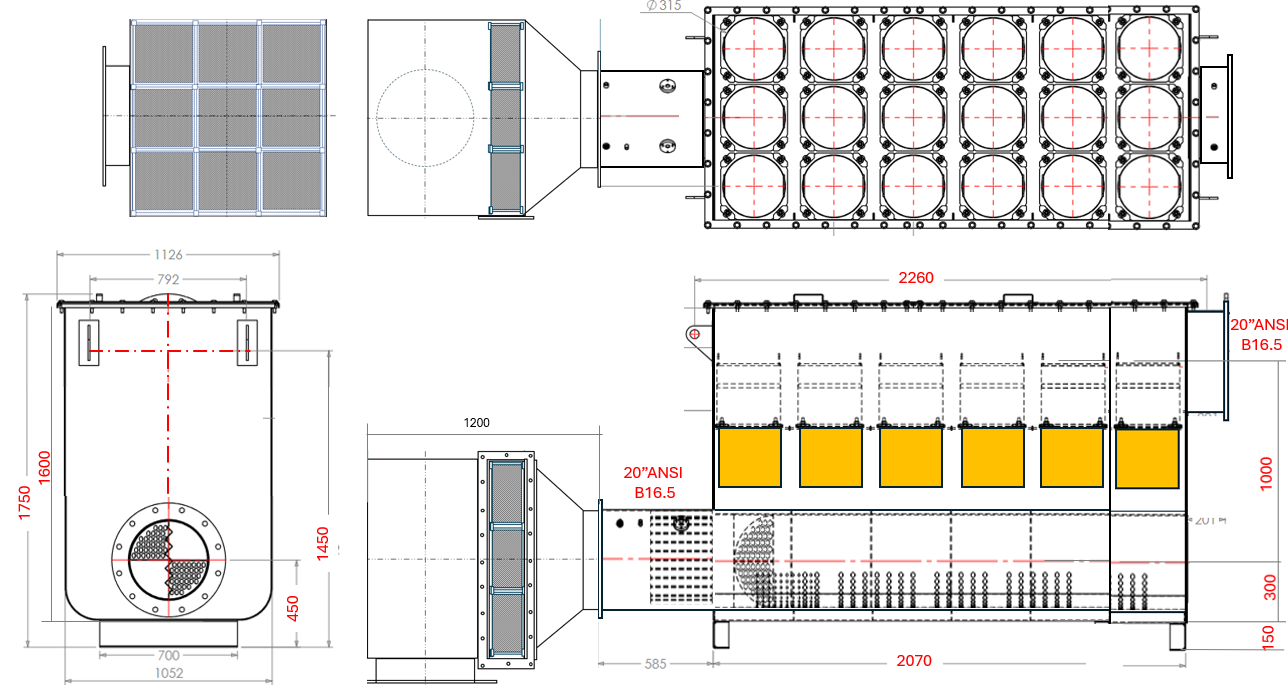

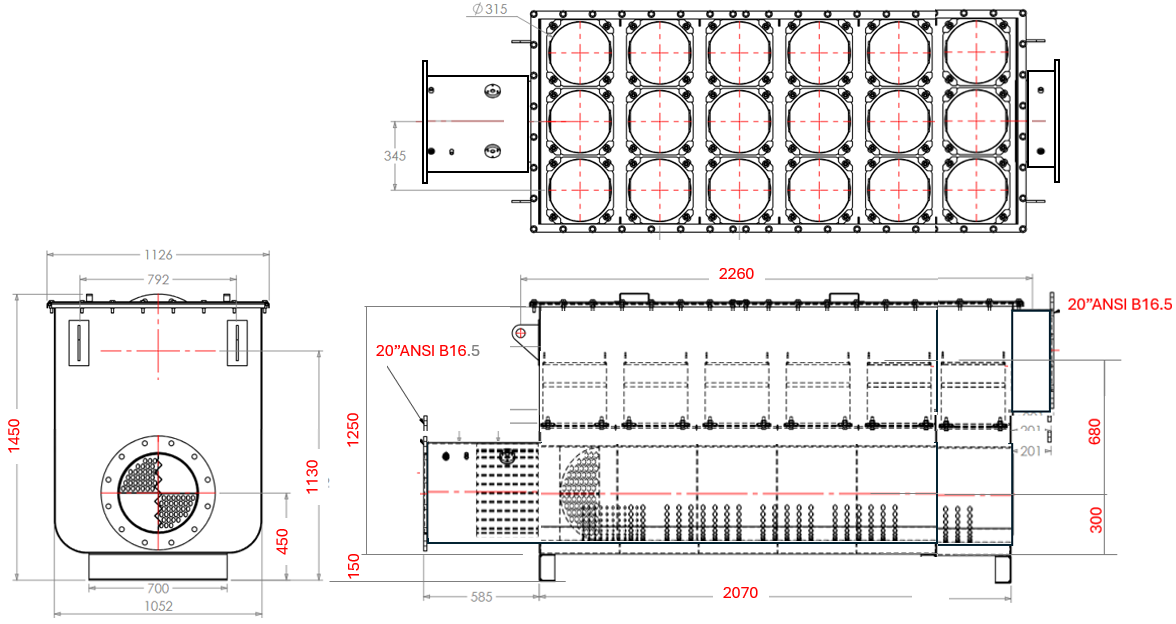

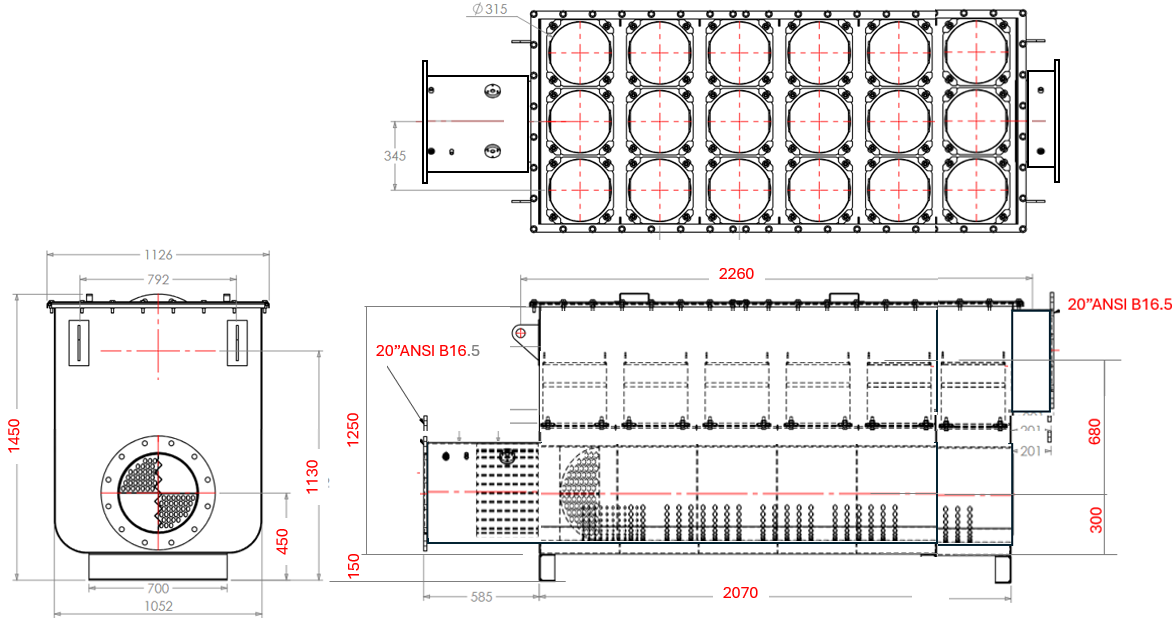

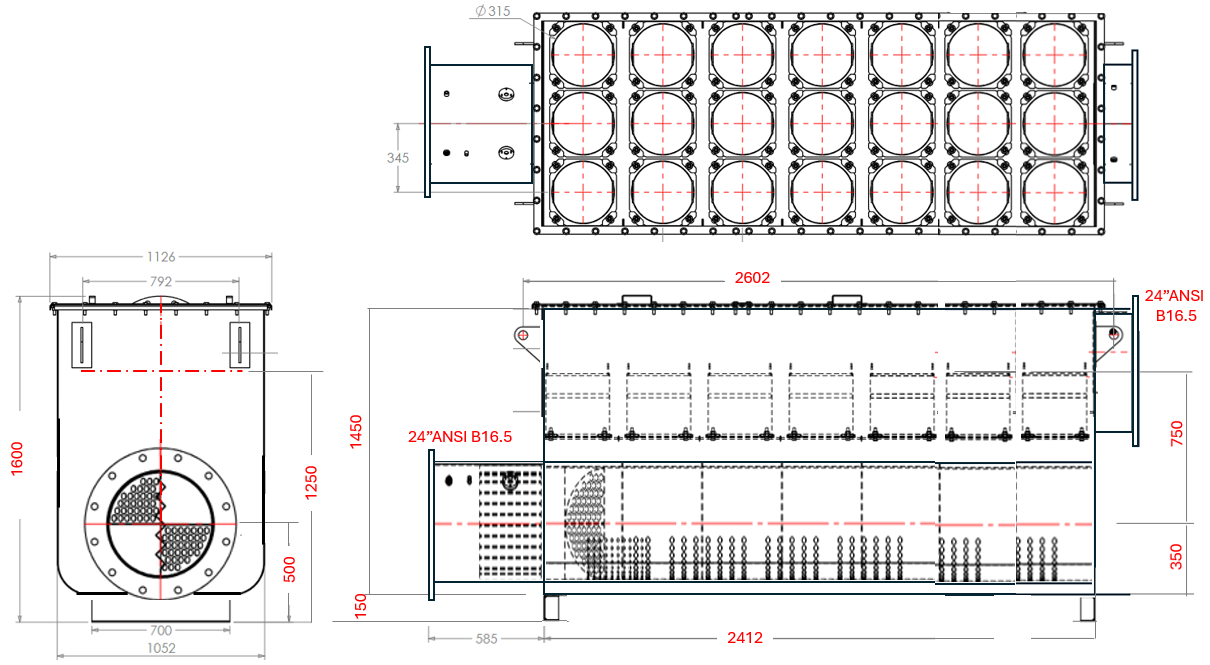

2. Rehlko KD62V12A (2813 kVA) – Diesel Engine for Mission‑Critical Power

Application Context

Used in industrial standby and mission‑critical facilities requiring Tier 4 Final compliance.

Key Engine Parameters

- 2250 kW

- 507 m³/min exhaust flow

- 450°C exhaust temperature

- 85 mbar max backpressure (40 mbar used by SCR‑ASC)

- 35 L/h DEF consumption

- Raw NOₓ: 8.9 g/kWh → 0.67 g/kWh (‑92% reduction)

- PM already compliant (no DPF required)

Airless SCR Design

- Diesel‑optimized catalyst

- Airless dosing for simplified installation

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for low‑frequency attenuation

Tier 4 Final Standards for KD62V12A (2813 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

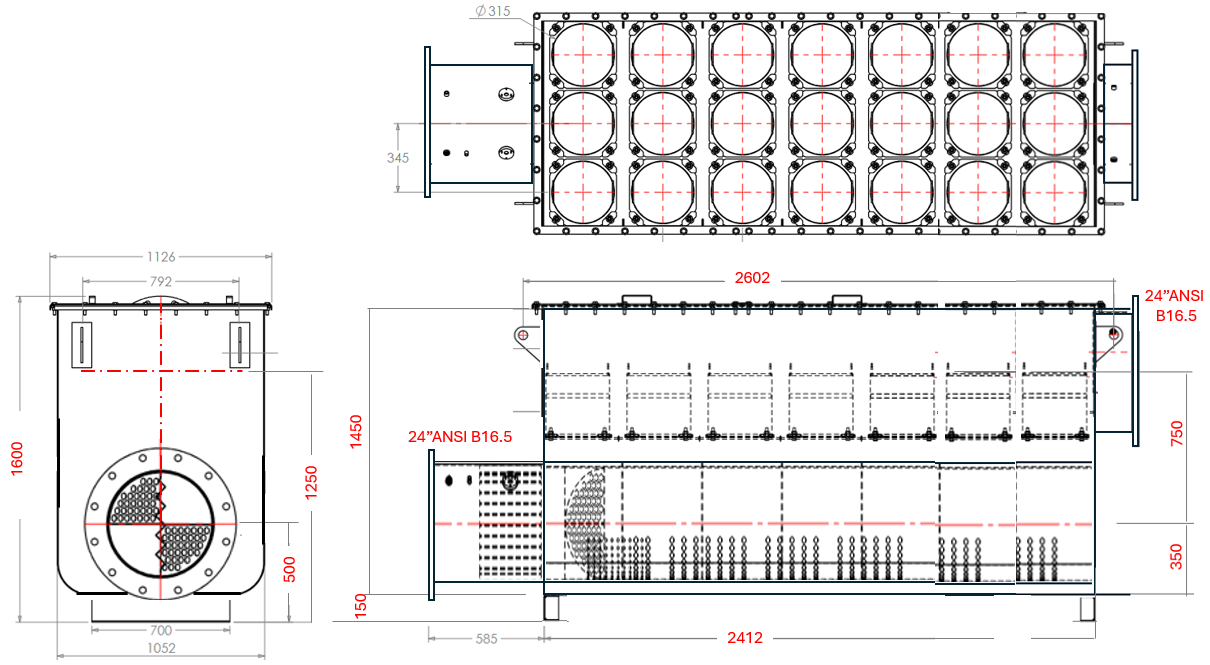

3. Rehlko KD62V12A (3125 kVA) – High‑Output Diesel for Industrial Standby

Application Context

Used in industrial standby and export markets requiring robust emissions control.

Key Engine Parameters

- 2500 kW

- 533 m³/min exhaust flow

- 470°C exhaust temperature

- 85 mbar max backpressure (42 mbar used by SCR‑ASC)

- 43 L/h DEF consumption

- Raw NOₓ: 8.7 g/kWh → 0.67 g/kWh (‑93% reduction)

- PM already compliant

Airless SCR Design

- High‑capacity SCR housing

- Modular catalyst blocks

- Airless dosing for reliability

Noise Control

- Integrated silencing

- Optional cladding for breakout noise

Tier 4 Final Standards for KD62V12A (3125 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

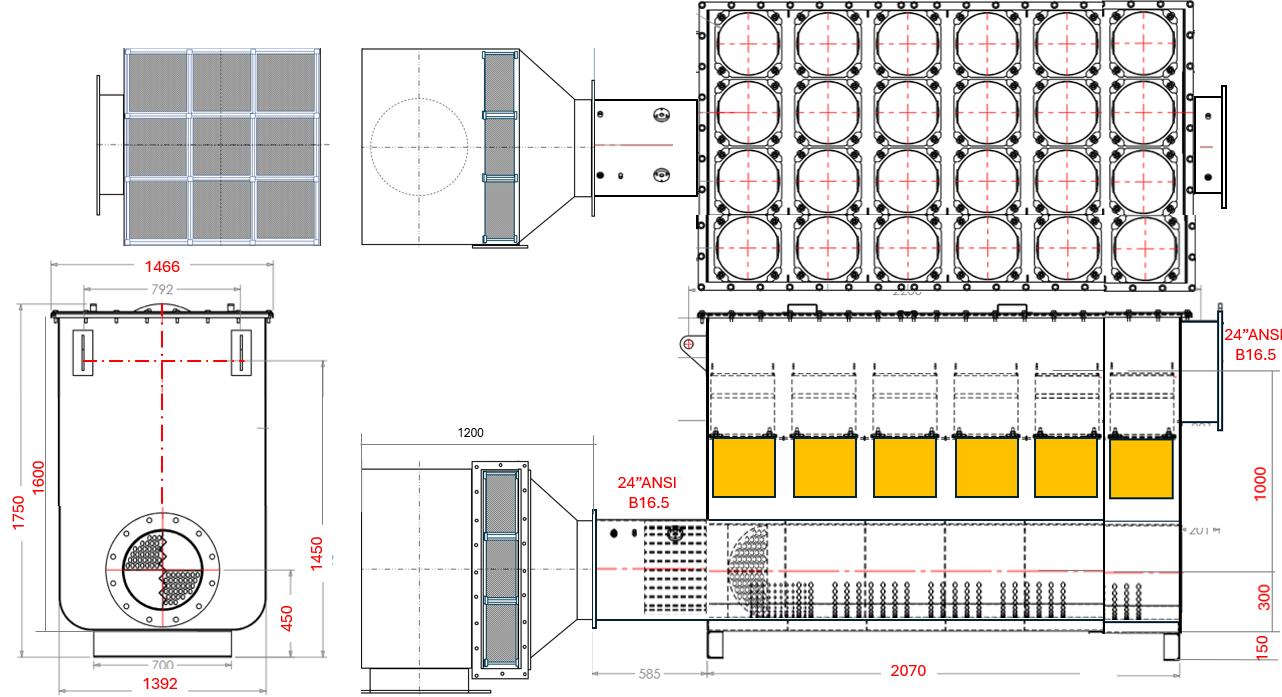

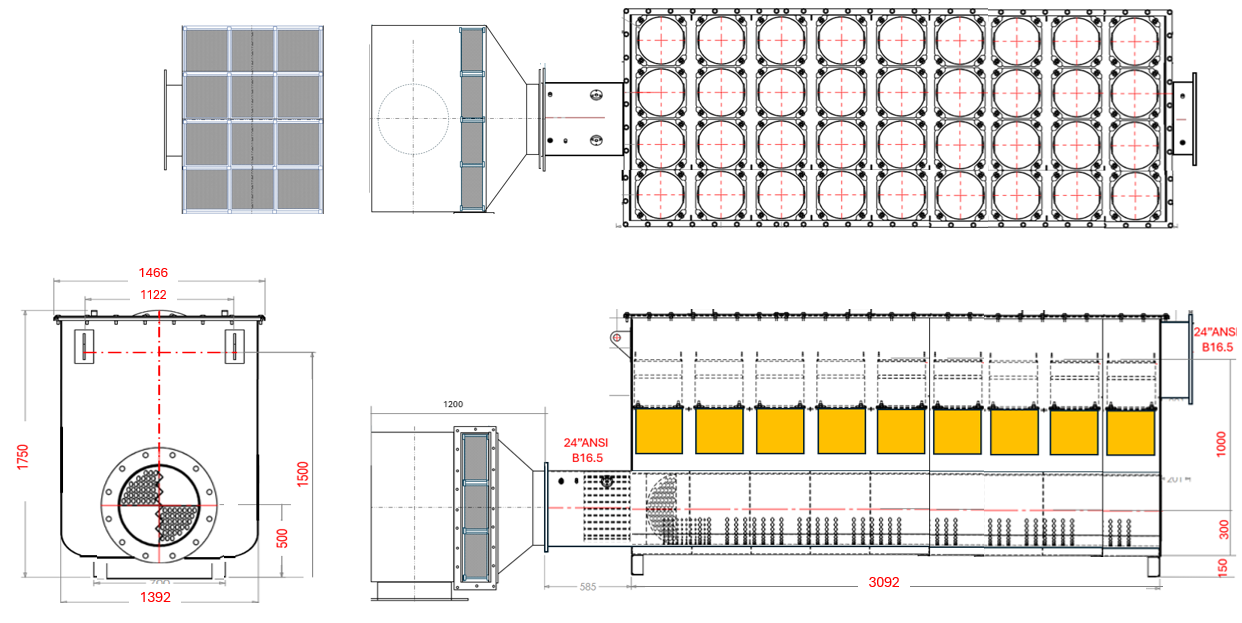

4. Rehlko KD83V16A (3500 kVA) – High‑Power Diesel for Industrial and Remote Power

Application Context

Used in mining, industrial standby, and remote installations requiring both NOₓ and PM reduction.

Key Engine Parameters

- 2800 kW

- 687 m³/min exhaust flow

- 474°C exhaust temperature

- 85 mbar max backpressure (58 mbar used by DOC/DPF/SCR‑ASC)

- 43 L/h DEF consumption

- Raw NOₓ: 7.8 g/kWh → 0.67 g/kWh (‑92% reduction)

- Raw PM: 0.04 g/kWh → 0.03 g/kWh (‑25% reduction)

Airless SCR Design

- Full aftertreatment chain

- Airless dosing for stable NOₓ control

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for low‑frequency control

Tier 4 Final Standards for KD83V16A (3500 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

5. Rehlko KD83V16A (3750 kVA) – Diesel Engine for Mission‑Critical Installations

Application Context

Used in datacenters, industrial standby, and export markets requiring Tier 4 Final compliance.

Key Engine Parameters

- 3000 kW

- 687 m³/min exhaust flow

- 474°C exhaust temperature

- 85 mbar max backpressure (44 mbar used by SCR‑ASC)

- 47 L/h DEF consumption

- Raw NOₓ: 8.0 g/kWh → 0.67 g/kWh (‑92% reduction)

- PM already compliant

Airless SCR Design

- Diesel‑optimized catalyst

- Airless dosing for simplified installation

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for breakout noise

Tier 4 Final Standards for KD83V16A (3750 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

6. Rehlko KD83V16A (4063 kVA) – High‑Output Diesel for Tier 4 Final Markets

Application Context

Used in industrial standby and mission‑critical facilities requiring robust emissions control.

Key Engine Parameters

- 3250 kW

- 716 m³/min exhaust flow

- 490°C exhaust temperature

- 85 mbar max backpressure (48 mbar used by SCR‑ASC)

- 55 L/h DEF consumption

- Raw NOₓ: 8.6 g/kWh → 0.67 g/kWh (‑93% reduction)

- PM already compliant

Airless SCR Design

- High‑capacity SCR housing

- Modular catalyst blocks

- Airless dosing for reliability

Noise Control

- Integrated silencing

- Optional cladding for low‑frequency attenuation

Tier 4 Final Standards for KD83V16A (4063 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

7. Rehlko KD103V20A (4370 kVA) – High‑Power Diesel for Industrial Standby

Application Context

Used in industrial standby and remote installations requiring both NOₓ and PM reduction.

Key Engine Parameters

- 3500 kW

- 812 m³/min exhaust flow

- 460°C exhaust temperature

- 85 mbar max backpressure (56 mbar used by DOC/DPF/SCR‑ASC)

- 48 L/h DEF consumption

- Raw NOₓ: 7.1 g/kWh → 0.67 g/kWh (‑91% reduction)

- Raw PM: 0.04 g/kWh → 0.03 g/kWh (‑25% reduction)

Airless SCR Design

- Full aftertreatment chain

- Airless dosing for stable NOₓ control

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for breakout noise

Tier 4 Final Standards for KD103V20A (4370 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

8. Rehlko KD103V20A (5000 kVA) – Multi‑Megawatt Diesel for Mission‑Critical Power

Application Context

Used in hyperscale datacenters, industrial standby, and export markets requiring Tier 4 Final compliance.

Key Engine Parameters

- 4000 kW

- 853 m³/min exhaust flow

- 480°C exhaust temperature

- 85 mbar max backpressure (42 mbar used by SCR‑ASC)

- 76 L/h DEF consumption

- Raw NOₓ: 9.7 g/kWh → 0.67 g/kWh (‑93% reduction)

- PM already compliant

Airless SCR Design

- High‑capacity SCR housing

- Modular catalyst blocks

- Airless dosing for simplified installation

Noise Control

- Integrated silencing

- Optional cladding for low‑frequency control

Tier 4 Final Standards for KD103V20A (5000 kVA)

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

9. Rehlko KD83V16 – Diesel Engine for Industrial Standby

Application Context

Used in industrial standby and mission‑critical facilities requiring emissions and noise control.

Key Engine Parameters

- 2500 kW (PRP) / 2800 kW (ESP)

- 644 m³/min exhaust flow

- 454°C exhaust temperature

- 85 mbar max backpressure

- 28 L/h AdBlue consumption

Airless SCR Design

- Diesel‑optimized catalyst

- Airless dosing for simplified installation

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for breakout noise

Tier 4 Final Standards for KD83V16

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

10. Rehlko KD36V16 – Diesel Engine for Medium‑Power Applications

Application Context

Used in industrial standby and commercial facilities requiring compact emissions solutions.

Key Engine Parameters

- 1180 kW (ESP)

- 241 m³/min exhaust flow

- 496°C exhaust temperature

- 85 mbar max backpressure

- 25–30 L/h AdBlue consumption

Airless SCR Design

- Compact SCR housing

- Airless dosing for simplicity

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for breakout noise

Tier 4 Final Standards for KD36V16

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

11. Rehlko KD27V12 – Diesel Engine for Light Industrial Applications

Application Context

Used in smaller industrial standby systems and commercial buildings requiring compact emissions solutions.

Key Engine Parameters

- 900 kW (Prime) / 1000 kW (Standby)

- 2.458–2.673 m³/s exhaust flow

- 530°C exhaust temperature

- 85 mbar max backpressure

- 28 L/h DEF consumption

Airless SCR Design

- Compact SCR housing

- Airless dosing for simplified installation

- Modular catalyst blocks

Noise Control

- Integrated silencing

- Optional cladding for breakout noise

Tier 4 Final Standards for KD27V12

| Emission | 2015 Standard |

|---|---|

| CO | 3.5 g/kWh |

| NMHC | 0.19 g/kWh |

| NOx | 0.67 g/kWh |

| PM | 0.03 g/kWh |

Final Thoughts

Airless SCR technology provides a reliable, low‑maintenance path to Tier 4 Final compliance across Rehlko’s most widely used engines. By integrating emissions reduction and acoustic attenuation into compact, modular systems, these solutions support datacenters, industrial facilities, and remote power installations where regulatory compliance and operational reliability are essential.

EI Williams Industries is actively expanding its library of ready‑engineered designs to include additional Rehlko engine platforms. This ongoing development ensures that engineers, consultants, and project teams have access to validated, application‑specific SCR and silencing solutions as new engines enter the market or regulatory requirements evolve.